The many modules of Numera

The Multiplexer Module

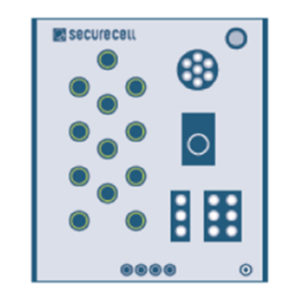

The Numera autosampler and analyser by Securecell provides a compelling PAT solution for your bioprocess sampling and analytics. Through this automation, your scientists and staff can now concentrate on interpreting data, and developing processes at an accelerated rate while maintaining comprehensive GMP compliance and thus ensuring patient safety.

The Numera system is comprised of a series of modules, allowing a bespoke system to be configured to suit the requirements of your research laboratory or manufacturing facility. In my previous article, I gave a brief summary of Numera, its many modules, and how they work together to sample and analyse your bioprocess samples. Below I discuss the multiplexer module in more detail and describe how its innovative design enables Numera to sample multiple bioreactors/fermenters at once while avoiding cross-contamination.

The multiplexer module forms the interface between your bioreactors/fermenters and the Numera system. It is capable of communicating with and sampling up to 16 bioreactors, meaning that multiple upstream processes can be run concurrently and evaluated. With this functionality, process-critical parameters can be monitored across varying conditions, allowing the best processes to be identified for manufacturing or further development. Furthermore, samples are taken in volumes of 2-4ml, ensuring minimal impact on process yields.

The multiplexer module forms the interface between your bioreactors/fermenters and the Numera system. It is capable of communicating with and sampling up to 16 bioreactors, meaning that multiple upstream processes can be run concurrently and evaluated. With this functionality, process-critical parameters can be monitored across varying conditions, allowing the best processes to be identified for manufacturing or further development. Furthermore, samples are taken in volumes of 2-4ml, ensuring minimal impact on process yields.

So, how is the multiplexer module able to sample across up to 16 concurrent upstream processes without cross-contamination?

A typical setup consists of an immersion nozzle occupying a port of a typical bioreactor or fermenter. This immersion nozzle is directly connected to the multiplexer module via a connection line, with both sterilized at the beginning of the process by autoclavation. The connection line enters the multiplexer module via a pinch valve, which opens only when a sample is drawn, thus preventing unsterile liquid to cross the sterile barrier. Samples are ferried from the multiplexer to their next intended module via the routing module. Between samples, the internals of the module is able to self-clean using ethanol, ensuring that no process material from one fermenter/bioreactor contaminates another.

With the ability to communicate with and sample up to 16 concurrent upstream processes, as well as maintaining sterility between individual samples; the multiplexer module performs a vital role in ensuring that Numera provides repeatable results, reliable data, and maintains CFR21 Part11 compliance for your bioprocess development.

To learn more about Numera by Securecell, please contact Sean Doran at BPES.

Article by:

Sean Doran

Technical Sales Specialist

E. sdoran@bpes.co.uk