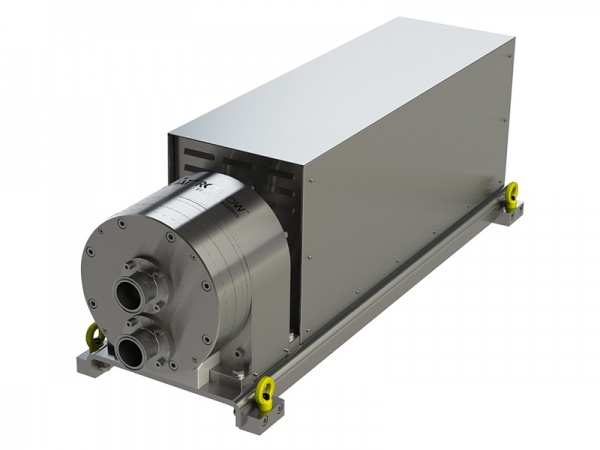

The new QF10k pump is equipped with an improved, patent pending stainless-steel pump chamber design that provides excellent drainability to maximize product recovery.

In addition, Quattroflow QF10k pumps incorporate a wide variety of other innovative features and benefits, including;

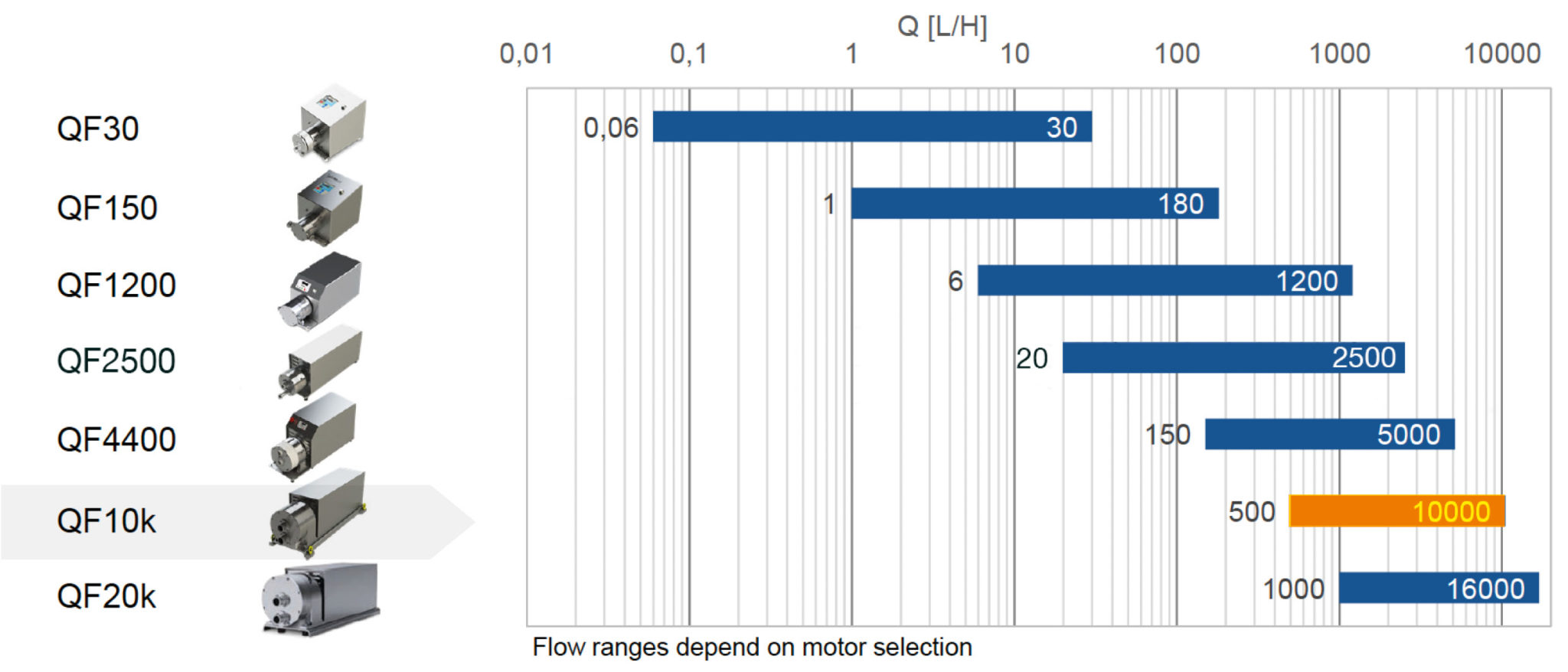

- 500 to 10,000 L/hr Flow range

- Applications include filtration systems (TFF, etc.), chromatography systems, feeding pump, virus filtration and sterile filtration

- 4-piston diaphragm positive displacement pump ensures total product containment

- Minimal maintenance and downtime required

- Low pulsation

- Low shear

- Superior containment

- Variable flow

- No particle shedding

- High purity

- Quiet operation

- CIP & SIP

- USP Class VI

- 20:1 turn-down ratio

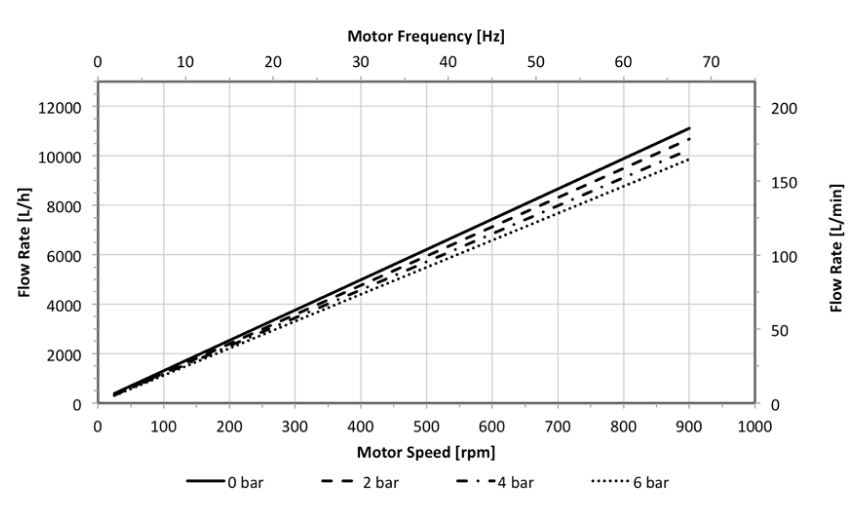

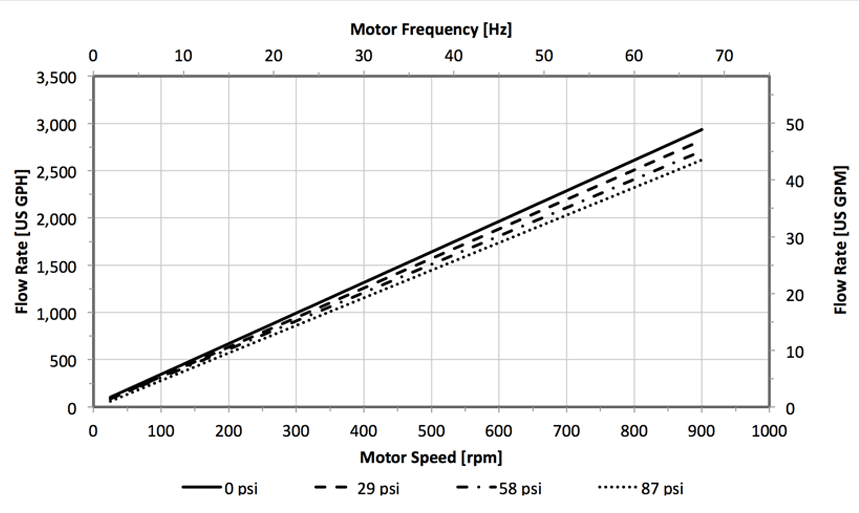

- Linear flow performance

Available accessories include control box, power box, diaphragm sensor and PID pressure controller.

Sean’s take on this product

Reliable: Quattroflow pumps are tried and tested across wide variety of biopharma applications. By providing low friction, low sheer, and low pulsation, they are ideal for critical applications in biopharma manufacturing such as Tangential Flow Filtration (TFF), Chromatography, centrifuge feed, and many more. Pumps are available in single as well as multi-use variants, giving you

Quality: Quattroflow pumps are well designed and engineered, offering a long product life with easily performed servicing. Service kits are available for all products, allowing them to be maintained in-house, or through your service contract-provider.

Did you know?

Quattroflow pumps are designed to mimic the human heart in order to give safe, reliable, and efficient transfer of biologics throughout your process.

Make an enquiry

Multi-Use Performance

Liter

Gallon

Multi-Use Technical Data

| QF10K STANDARD MOTOR | ||

|---|---|---|

| Flow Rate Maximum | Eccentric Shaft 6° | 10000 lph (167 lpm) |

| Flow Rate Minimum | Eccentric Shaft 6° | 500 lph (8.3 lpm) |

| Pressure | Temperature of Fluid < 40°C (104°F) | 6 bar (87 psi) |

| Temperature of Fluid > 40°C (104°F) | 4 bar (58 psi) | |

| Maximum Temperature | Fluid | 80°C (176°F) |

| CIP | 90°C (194°F) | |

| SIP | 130°C (266°F) | |

| Autoclave | 130°C (266°F) | |

| Suction Lift Dry at 1,800 rpm | Eccentric Shaft 6° | 4 – 4.5 m (13.1-14.7 ft) |

| Volume Specifications | Approximated Volume per Revolution at Free Output |

194 ml |

| Filling Volume Without Connectors | 1,300 ml | |

| Connection Specification (Standard) | Connectors | 2″ TC |

| Position of Connectors | Front | |

| Product Wetted Materials (Standard) | Pump Housing | SS316L |

| Valve Plate | SS316L | |

| Diaphragms | TPE | |

| Valves | EPDM | |

| O-rings | EPDM | |

| Certificates/Proofs (Optional) | Elastomere (product wetted) | USP <88> Cl. VI; FDA21CFR177; BSE/TSE Safe |

| Stainless Steel Parts (product wetted) | 3.1; Surface Roughness; Ferrite Content | |

| Motor (Standard) | Rated speed | 2,894 min-1 (50 Hz) |

| Voltage | 230/400 V | |

| Power | 3.0 kW | |

| Gear | 4.32:1 | |

| Pump Dimension with Motor and Housing | Length | 1155 mm (45.48″) |

| Width | 437 mm (17.20″) | |

| Height | 430 mm (16.38″) | |

| Pump Weight with Motor and Housing | 185 kg (408 lb) | |